Nihon Superior Centre for the Manufacture of Electronic Materials

The Nihon Superior Centre for the Manufacture of Electronic Materials bringing world-class research capability to the manufacture of electronic materials.

The objective of the centre is to enable The University of Queensland and Nihon Superior Co. Ltd to continue their significant history of strategic and collaborative research.

The Centre specialises in the development of lead-free soldering and brazing alloys and the manufacture of materials for energy storage and transport materials including hydrogen storage and novel solid-state anode materials. The Centre has a strong focus on commercially relevant and environmentally sustainable research.

Research

2019 Highlights

PhD Student Research Program Content and highlights

1. Ms Syeda Mehreen’s PhD project

Ms. Syeda U. Mehreen had the chance to conduct in situ directional solidification experiments at the SPring-8 Synchrotron Facility in Hyōgo Prefecture, Japan. Her research project is aimed at investigating the potential for Sn-Cu alloys to be developed as high-temperature solders. The Sn-Cu alloys used as high-temperature solders involve the formation of a needle-shaped Cu3Sn phase and a secondary phase, Cu6Sn5 forms around the primary Cu3Sn and thickens, eventually encapsulating the Cu3Sn completely, whereby Cu3Sn remains in the microstructure. The presence of Cu3Sn has not been desirable due to concerns associated with its brittleness, possibly attributed to its elongated needle-shaped structure which may reduce solder performance. The focus of this research is to explore possible means of removing Cu3Sn in the bulk solder itself, thereby facilitating the development of Sn-Cu solders for high-temperature applications. Ni has been investigated as a potential means for Cu3Sn suppression. With previous experiments, she achieved Cu3Sn suppression in the bulk alloy Sn-10Cu-xNi (x = 0.06wt.%-1wt.%). Therefore, the next step was aimed at understanding the solidification sequence of Sn-10Cu-xNi alloys by real-time in situ directional solidification. The real-time observation of the solidification process is key to providing vital information for studying the dynamics of phase formation in these alloys. This opportunity to conduct experiments at SPring-8 has helped Ms. Syeda U. Mehreen to confirm the suppression of Cu3Sn from both the perspective of alloy Ni additions to Sn-10Cu as well as the effect of pull rate on Cu3Sn formation.

2019 International Conference on Nanospace Materials (ICNM), Brisbane, Australia

Ms. Syeda U. Mehreen delivered her paper presentation in ICNM 2019 held at The University of Queensland, Brisbane, Australia in October, 2019. The conference attracted world-class researchers to share topics within the Nanospace Architecture domain. A diverse presence ranging from industry representatives to research collaborators/ partners attended the ICNM 2019 Conference. She presented a holistic view of the different approaches to remove the primary phase from the microstructure of peritectic alloys with examples from literature and her work.

The Electronic Packaging Interconnect Technology Symposium (EPITS) and Synchrotron Workshop, Penang, Malaysia

Ms. Syeda U. Mehreen delivered her paper presentation in EPITS 2019 International Conference held at Penang, Malaysia in November 2019. The conference was co-ordinated by Universiti Malaysia Perlis and supported by Nihon Superior Ltd. She presented her work on using Nickel and Zinc as potential alloying elements that can be added to Sn-Cu systems to remove the potentially brittle Cu3Sn phase.

Ms. Syeda U. Mehreen published this work as a conference paper, titled, “Effect of Zn addition on Cu3Sn formation in Sn-10Cu alloys”. The citation is as follows:

Mehreen, S.U., Nogita, K., McDonald, S. and StJohn, D., 2019, December. Effect of Zn addition on Cu3Sn formation in Sn-10Cu alloys. In IOP Conference Series: Materials Science and Engineering (Vol. 701, No. 1, p. 012009). IOP Publishing.

Ms. Syeda U. Mehreen also attended the Synchrotron Workshop that was jointly held at EPITS 2019. The topics at the workshop revolved around the importance of synchrotron light and how that power source can be utilised for many different techniques such as X-ray powder Diffraction (XRD), X-ray photoelectron spectroscopy (XPS), X-ray absorption spectroscopy (XAS).

2. Mrs Flora Somidin’s PhD project

2019 progress updates

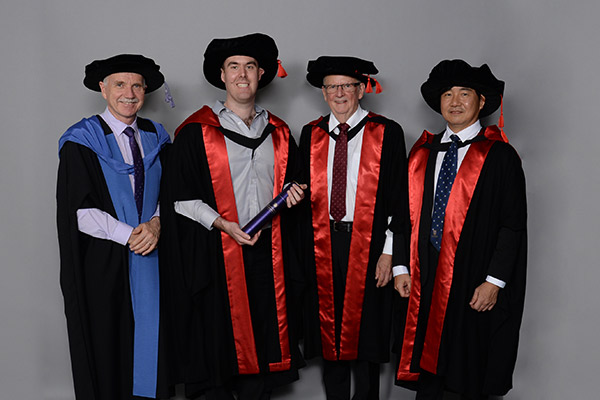

Mrs. Flora submitted her thesis on 31st October 2019 for evaluation from external examiners. On 16th March 2020, she was awarded her Ph.D. degree in the field of materials engineering from the School of Mechanical and Mining Engineering, University of Queensland, Australia.

Ph.D. thesis title: Phase Transformation Considerations in Manufacturing Reliable Sn-rich Solder joints

Ph.D. thesis short abstract: The legislated removal of lead (Pb) from solders used in the electronics sector has seen a range of primarily Sn-based Pb-free solders developed over the past decade. When these solders react with Cu substrates in printed circuit boards of electronic packaging systems, the dominant intermetallic that results will be Cu6Sn5. The thesis includes three major outcomes: in-situ high voltage transmission electron microscopy observation of polymorphic phase transformation of Cu6Sn5 in real solder joint, inhibitory effect on polymorphic phase transformation of Cu6Sn5 by Ni alloying, and investigation of manufacturing of reliable solder joints by reducing cracking using the developed time-temperature-transformation diagram of Cu6Sn5.

2019 publications included in the thesis:

1. F. Somidin, H. Maeno, T. Toriyama, S. D. McDonald, W. Yang, S. Matsumura, K. Nogita, Direct observations of the Ni stabilising effect in interfacial (Cu,Ni)6Sn5 intermetallic compounds, Materialia, 9 (2020) 100530. DOI: https://doi.org/10.1016/j.mtla.2019.100530.

2. F. Somidin, S. D. McDonald, X. Ye, D. Qu, K. Sweatman, T. Akaiwa, T. Nishimura, K. Nogita, Reducing cracking in solder joint interfacial Cu6Sn5 with modified reflow profile, Submitted to Journal of the Japan Institute of Electronics Packaging on 18th July 2019.

10-14 March 2019: 2019 TMS Annual Meeting & Exhibition, San Antonio, Texas, USA

Presentation title: "Phase transformations induced cracking in solder joints containing Cu6Sn5"

Abstract: In isolated samples of Cu6Sn5 there is significant evidence that there is a polymorphic phase transformation that is sensitive to composition (including trace elements) and cooling/heating rate. It has been hypothesised that this is a mechanism of cracking in samples subjected to thermal cycling. However, there has been little direct evidence of the transformation in constrained solder joints that contain multiple phases as well as an adjacent substrate. This research uses a systematic approach to characterise the structural evolution of a single targeted Cu6Sn5 grain constrained between Sn rich and Cu‐Cu3Sn phases using high‐voltage Transmission Electron Microscopy (HV‐TEM) equipped with an Omega energy filter. A time‐temperature‐transformation (TTT) diagram was developed and used to inform a sequence of thermal cycling to investigate the propensity for cracking. The results show for the first time the relationship between cracking and phase transformations in the Cu6Sn5 of solder joints.

1-4 October 2019: 2019 International Conference on Nanospace Materials, Nanoarchitects in Nanospace Materials, The University of Queensland, St Lucia Campus, Australia.

Presentation title: "Constructing a time-temperature-transformation curve for Cu6Sn5 using in situ high-voltage TEM"

Abstract: The intermetallic Cu6Sn5 typically forms as an interfacial layer in the soldering reaction between Sn-based solder alloys and Cu substrates. During the soldering process, the high temperature hexagonal η-Cu6Sn5 (P63/mmc) phase that forms on the Cu substrate can transform to a monoclinic η’-Cu6Sn5 (C2/c) variant during cooling from >186 °C to room temperature. While the polymorphic transformation of bulk structures of Cu6Sn5 has been extensively studied by methods including XRD and DSC, the results provide little insight into the mechanisms of the transformation occurring in individual Cu6Sn5 grains present in more commercially relevant structures. A direct observation of the transformation in a real solder joint is required before the results can be more generally applied. In this study, we present a novel method to construct a time-temperature-transformation (TTT) curve of the η↔η’ transformation in a single targeted Cu6Sn5 grain constrained between Sn-rich and Cu-Cu3Sn phases using in situ high-voltage Transmission Electron Microscopy (HVTEM) equipped with an Omega energy filter. The method provides a new approach for further understanding and potentially controlling the solid-state transformations in a variety of solder systems in micro-alloyed Pb-free solder joints. Importantly, the results are of great scientific interest and the technique could find application in characterising phase transformation in targeted locations of other materials.

Presentation title: "Influence of cooling conditions on the interfacial Cu6Sn5 intermetallic compound in Sn-37Pb/Cu solder joints during reflow"

Abstract: Despite a shift to Pb-free solders in the majority of electronic assemblies, Pb-containing solders are still used in a variety of applications. Recent research has revealed the complexities of the intermetallic Cu6Sn5 in terms of its crystal structure and stability when present as the reaction product between Pb-free solders and common substrates. In light of these findings, the effect of multiple reflow cycles with different cooling conditions on the microstructure of the interfacial Cu6Sn5 intermetallic compound (IMC) between Sn-Pb solders and Cu substrates was re- examined. For this purpose, the Sn-37Pb (in wt.%) solder was reflowed on a Cu substrate at a temperature of around 240 °C and cooled at a rate of around 30 °C/min under each of two conditions; (i) direct-cooling to room temperature, and (ii) interrupted-cooling with extended isothermal holding periods of 30 and 180 seconds at 140 °C. This second condition was chosen to encourage the polymorphic transformation that occurs in the Cu6Sn5 (at an equilibrium temperature of 186 °C) at a temperature which minimises the stresses involved. Smaller cracks and a thinner interfacial IMC layer were observed in the solder joints that were reflowed repeatedly with the interrupted-cooling conditions. However, despite the higher number of cracks in the samples undergoing conventional reflow, the shear strength was not significantly affected.

Publication: F. Somidin, S. McDonald, T. Akaiwa, T. Nishimura, and K. Nogita, “Influence of cooling conditions on the interfacial Cu6Sn5 intermetallic compound in Sn-37Pb/Cu solder joints during reflow,” IOP Conference Series: Materials Science and Engineering, vol. 701, p. 012006, Dec. 2019, doi: 10.1088/1757-899x/701/1/012006.

3. Ms Shiqian Liu’s PhD project

Ms Shiqian Liu presented her work about the interaction of Ga-based alloys and Cu substrates at low temperatures at the 2019 TMS Annual Meeting & Exhibition on 13 March 2019 at San Antonio, Texas, USA.

Ms Shiqian Liu was invited to visit Central South University, Changsha, China in November 2019. She presented her work about the interaction of Ga-based alloys and Cu substrates at low temperatures in the School of Minerals Processing and Bioengineering, and the School of Materials Science and Engineering.

4. Ms Xin Fu Tan’s PhD project

Ms. Xin Fu Tan received a postgraduate research award (PGRA), a living stipend top-up scholarship sponsored by the Australian Institute of Nuclear Science and Engineering (AINSE). She also attended the orientation week in the nuclear facilities in Lucas Heights, New South Wales. There were 23 scholars from both PGRA and RSS (residential student scholarship), who attended the o'week, including 6 from NZ and the rest from AU (2 from UQ, the other one is an RSS holder from Science Faculty). Leaders from various ANSTO facilities in Lucas Heights gave talks about their respective units and a facility tour was held.

Ms. Xin Fu Tan was selected as one of 6 research students/early career researchers sponsored by Australia to attend the 3rd Asia Oceania Forum Synchrotron Radiation (AOFSRR) School, held at the National Synchrotron Radiation Research Center (NSRRC), Hsinchu, Taiwan. The venue is also where the Taiwan Light Source (TLS) and Taiwan Photon Source (TPS) are located. 48 participants including Masters and PhD students, early career researchers from universities and synchrotron facilities in the Asia Oceania region attended the event.

The school’s curriculum covers the fundamentals of synchrotron radiation, crystallography, scattering & X-ray matter interaction, various beamlines and their applications. The other activities include a tour of the TPS, beamline specific activities including tutorials, beamline practice, data analysis and student presentations.

5. Mr Manjin Kim’s PhD project

Mr. Manjin Kim attanded 9th International Light Metal Technology Conference (LMT 2019), Shanghai, China. He made an oral presentation with the topic “Solidification microstructures in the Mg-rich corner of the Mg-Al-La” at the conference. He also presented his research topic “Effect of Na addition and cooling rate on activation of Mg-Ni alloys for hydrogen storage” at a poster session, 2019 International Conference on Nanospace Materials (2019 ICNM), Brisbane, Australia. Based on his research results, he published a paper “Effect of Na addition and cooling rate on the activation of Mg-Ni alloys for hydrogen storage systems” in the Journal of Nanoscience and Nanotechnology and a proceedings “The Independent Effects of Cooling Rate and Na Addition on Hydrogen Storage Properties in Hypo-eutectic Mg Alloys” in Mgnesium Technology 2020.

Mr. Manjin Kim was awarded $5,000 travel funding for an internship at the Nihon Superior R&D Centre in Osaka, and a traineeship at The Ultramicroscopy Research Centre, Kyushu University, Fukuoka, Japan (19 Oct 2019 to 19 Jan 2020). He conducted experiemnts on high-voltage transmission electron microscopes at Kyushu University to study about the hydrogen desorption behavior of Mg-La alloys. He also conducted Porosity Distribution Observation of Cu-xNi/Ga/Cu-xNi lap joint using resonant ultrasound spectroscopy (Sonoscan D9600TM) at Nihon Superior R&D Centre.

6. Ms Nurul Razliana Abdul Razak’s PhD project

Development of full intermetallics solder joints using Sn-Cu systems through transient liquid phase (TLP) method have already received significant attention due to their potential to be applied as an alternative for high temperature interconnection application. On 10–12 June 2019, an in-situ heating observation was done on the fast growth of the Cu6Sn5 intermetallics resulting from the reaction of the Sn-Cu solder with Cu-Ni substrates. Observations were made using the high resolution of Synchrotron real-time X-ray imaging located at BL20XU. From this study, other than the fast growth of the intermetallics, the mechanism of porosity formation in TLP processes was also observed.

Nurul Razliana Abdul Razak delivered her paper presentation in the Electronic Packaging Interconnects Symposium (EPITS 2019) held at Bayview Beach Resort, Penang, Malaysia in November 2019. This conference brings a multi-disciplinary group of scientist and engineers from different countries such as Malaysia, China, Japan and Australia to present and exchanges ideas related to the electronic packaging. Razliana’s paper was presented was published in IOPScience Conference Series as follows:

Razak, N. R. A., Tan, X. F., McDonald, S. D., & Nogita, K. (2019). Interfacial reactions between different Sn-based lead-free solder alloys and CuNi substrates. IOP Conference Series: Materials Science and Engineering, 701, 012008.

In conjunction of the conference, a workshop related to synchrotron was held with several speakers who are experienced with Spring-8 Synchrotron, Japan and Synchrotron Light Research Institute (SLRI), Thailand.

Facilities

The Centre is equipped with sample production, processing and analysis equipment and softwares to facilitate advance research.

The Centre is equipped with sample production, processing and analysis equipment and softwares to facilitate advance research.

These are summarised in the list below:

- Tabletop SEM/EDS Hitachi TM3030 and TM1000

- Sputter coater (with Au, Ag, Pt targets)

- MBraun UNIlab glovebox with oxygen and moisture monitoring

- Manual purge glovebox

- Reflow oven

- Heratherm annealing ovens

- Microwave oven

- Bridgeman furnace

- 3D printer

- Battery testing equipment

- Coin cell assembly equipment

- Durston double power mills

- Turbula ball milling cell

- Sieve stacks and sieve shakers

- Gravimetric hydrogen storage testing equipment

- Ultrasonic cleaner

- VASP 5.4.4 group license

- Thermo-Calc 2022a license

- TOPAS commercial license

- TOPAS academic licenses

- CrystalMaker and Single Crystal licenses

- IGOR Pro license

- Image-Pro Premier license

- GeoPIXE license

- FEFF9 license

The Centre also has access to a comprehensive suites of apparatus housed at The University of Queensland.

A list of such apparatuses is provided below:

- Induction melting furnaces

- Arc melting furnaces

- Electric resistance furnaces

- Heat treatment furnaces

- Air circulation oven

- Thermal analysis equipment

- Sand mixer

- Powered hacksaw and bandsaw

- Fume cupboards

- Epoxy mounting kit

- Struer CitoPress-30 hot mounting press

- Wafering saws

- Wheel cutters

- Struer autopolishers

- Heater stirrers

- Ultrasonic bath

- Engraver

- Electropolisher

- Rolling mill

- Various optical microscopes

- Free standing grinding belt

- Zwick impact tester

- Charpy impact tester

- Hardness tester

- Optical microscopy

- Optical Emission Spectroscope (OES)

- TEM (Transmission Electron Microscopy)

- SEM/EDS/EBSD (Scanning Electron Microscopy/Energy Dispersive X-Ray Spectroscopy/Electron Backscatter Diffraction)

- FIB (Focused Ion Beam)

- Lab XRD (X-Ray Diffraction)

- XPS (X-Ray Photoelectron Spectroscopy)

- Sample coater (carbon, iridium, platinum coating)

- DSC (Differential Scanning Calorimetry)

- Surface profiler (Atomic Force Microscopy)

- Nano-indentation

- Suzuki Shokan Sievert hydrogen storage testing machine

- Sample chemical etching

NS CMEM has also been successful with frequent accesses to facilities external to the University of Queensland, often yielding significant discoveries and research advances.

- Australian Synchrotron Powder Diffraction beamline

- Australian Synchrotron XFM beamline

- SPring-8 Synchrotron X-Ray Radiography

- SPring-8 Synchrotron micro XRF (X-Ray Fluorescence)

- Kyushu University HVTEM (High Voltage TEM)

- Kyushu University ARM-TEM (Atomic Resolution Microscope TEM)

News and engagement

2021

- Acta Student Award

- Dr Flora Somidin, Phd graduate under Nihon Superior Centre for the Manufacture of Electronic Materials (NS CMEM), School of Mechanical and Mining Engineering, received a prestigious Acta Student Award for her Thesis.

- TMS2021 Light Metals Magnesium Best Poster Award

- PhD candidate Mr Manjin Kim is awarded the 'TMS Light Metals Magnesium Best Poster Award' at TMS2020 for his poster "Eutectic Modification of Mg2Si in Mg-Si Alloys for Faster Hydrogen Absorption Kinetics". The award recognises the individual excellence of a poster in the area of magnesium technology presented at the preceding year's TMS Annual Meeting.

2020

- TMS2020 Research to Industrial Practice Award

- Professor Nogita is awarded the '2021 Research to Industrial Practice Award'.

- TMS2020 LMD Magnesium Technology Best Student Paper Award

- PhD candidate Mr Manjin Kim is awarded the 'TMS LMD Magnesium Best Student Paper Award' at the Light Metals Division at TMS2020. The Award is given in recognition of excellence in authorship of an outstanding technical paper for his work entitled "The Independent Effects of Cooling Rate and Na Addition on Hydrogen Storage Properties in Hypo-Eutectic Mg Alloys".

- PhD candidate Mr Manjin Kim is awarded the 'TMS LMD Magnesium Best Student Paper Award' at the Light Metals Division at TMS2020. The Award is given in recognition of excellence in authorship of an outstanding technical paper for his work entitled "The Independent Effects of Cooling Rate and Na Addition on Hydrogen Storage Properties in Hypo-Eutectic Mg Alloys".

2019

- ICEP2019 Outstanding Technical Paper Award

- For a second consecutive year a paper reporting the results of projects undertaken as collaborations between the University of Queensland’s Nihon Superior Centre for the Manufacture of Electronic Materials (NS CMEM) and an overseas university has been recognized as an Outstanding Technical Paper by the organising committee of one of the world’s leading international electronics industry conferences, International Conference on Electronics Packaging (ICEP 2019) in Niigata, Japan.

- Best of Conference award at SMTA International 2018

- Professor Nogita is awarded the 'Rich Feiberger Best of Conference' at the SMTA International Conference and Exhibition, which took place from October 14 – 18, 2018 at the Donald E. Stephens Convention Center in Rosemont, USA.

Engagement highlights

2019 engagement highlights

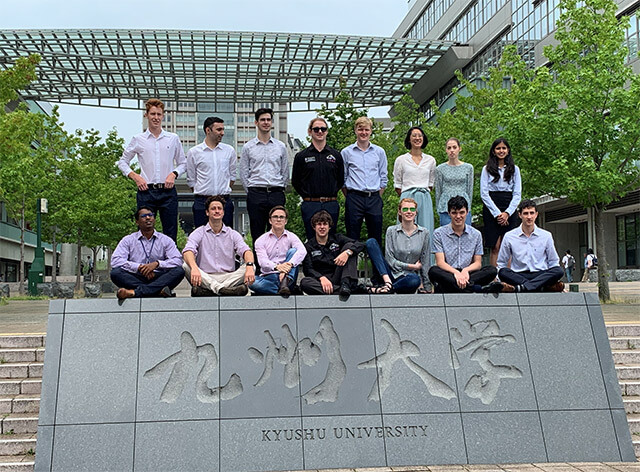

UQ-KU Project and research collaborations with KU (Kyushu University)

(Dr. Kazuhiro Nogita, Project Manager)

To increase the practical collaboration between the University of Queensland (UQ) and Kyushu University (KU), the “UQ-KU Project” was established on 16th December 2015. The main target of this project is to facilitate collaborative activities through the coordinators based at UQ and KU. The appointed coordinators are Prof. Syo Matsumura of the Graduate school of Engineering at KU and Assoc. Prof. Kazuhiro Nogita of the School of Mechanical and Mining Engineering at UQ, who is an alumnus of KU. The project provides an avenue for: (1) academic exchange (undergraduate and graduate student exchange, researcher exchange, joint research publications and presentations); (2) education opportunities (lectures, education projects, and industry-university collaborations); (3) support services (communications and public affairs, exchange student assistance). After successful completions for three years the UQ-KU project between April 2015 to March 2018, UQ-KU project was extended three years from April 2018 to March 2021. In 2019, Mr Manjin Kim and Mr Youichirou Kawami stayed at Prof. Matsumura’s lab at Kyushu University. Prof Kazuhiro Nogita with 15 UQ Engineering students travelled to Kyushu University as part of the Australian Government New Colombo Plan in the first two weeks of July. This programme was facilitated by the UQ-KU Oceania Project and the Kyushu Economic Federation (KEF). The UQ-JPIE program is designed to give the visiting UQ undergraduate engineering students’ first-hand exposure to world-leading Japanese industry and supporting research that is done in Science, Technology, Engineering and Mathematics at Kyushu University. The UQ-JPIE program for 2019 included visits to the J-Power, Bridgestone Kitakyushu Plant, Nippon Steel & Sumitomo Metal Corporation, Yaskawa Electric Corporation, Mitsubishi Heavy Industries (shipbuilding), TOTO (ceramics), SUMCO, Mitsubishi Electronics (Power Devince) and Toyota Motor Kyushu. Prior to the industry visits, the UQ students were fortunate to receive a preparatory lecture from one of Kyushu University’s experts for each particular industry. In addition, there were further lectures from Kyushu University’s leading researchers across a variety of fields.

2. The Electronic Packaging Interconnect Technology Symposium 2019

(Dr. Kazuhiro Nogita, Co-Chair)

Dr Nogita (UQ) will co-chair/co-organise EPITS2019 with UniMAP

On 24 and 25 November 2019, CEGeoGTech Universiti Malaysia Perlis (UniMAP) organised the 2nd Electronic Packaging Interconnect Technology Symposium 2019 (EPITS2019) in collaboration with UQ. The conference was held at Penang Malaysia, and over 100 people have joint the symposium. From UQ 6 persons (Dr. Kazuhiro Nogita, Ms Syeda Mehreen, Ms. Flora Somidin, Ms Shiqian Liu, Ms Xin Fu Tan, Ms Nurul Razliana Abdul Razak) had attended the symposium. EPITS2019 was specifically aimed to bring together technologist, researchers and professionals from the Academic, Industrial and Public sectors in the context of a multi and inter-disciplinary forum and discussion. The symposium has provided an excellent opportunity for intellectual discourse on demonstration of advances and research results in the field of Electronic Packaging Interconnect Technology. This event has brought various researchers, academics, and industry leaders from six countries to discuss and debate about the state-of-art and future trends in electronic packaging technology. The symposium was mainly led by Dr. Mohd Arif Anuar Mohd Salleh (Chairman). The symposium was successfully held with the help of the working committee members who provided technical and scientific support in helping to make the symposium run smoothly.

3. Nihon Superior Malaysia (Ipoh) visit

(Dr. Kazuhiro Nogita, Ms Syeda Mehreen, Ms. Flora Somidin, Ms Shiqian Liu, Ms Xin Fu Tan, Ms Nurul Razliana Abdul Razak)

After EPITS2019 symposium, UQ delegations visited Nihon Superior Malaysia (NSM) in Ipoh to discuss collaborative research projects and tour NSM’s production and R&D facility.

Presentations and highlights

1. Presentations and lecturing at Central South University, China

(Prof Kazuhiro Nogita, Director)

Prof. Nogita delivered two lecture series and one presentation listed below during his visit from 21st October to 1st November 2019 at Central South University, China. Prof. Nogita was invited by Prof. Guang Zeng who is a UQ PhD graduate previously under Prof. Nogita and Dr. McDonald’s supervision.

Delivered lectures:

- “Casting” for CSU international undergraduate students

- “Eutectic solidification and their application for manufacture of energy materials” for CSU graduate students Delivered presentation:

- “Advanced characterisation of materials: R & D case studies”

2. Presentation and lecturing at UniMAP, Malaysia

(Prof Kazuhiro Nogita, Director)

Prof. Nogita delivered a lecture “Advanced characterisation of materials: case studies” and presentation “Research history in industry and overseas university experience in nuclear and energy storage materials” during his visit from 20th to 23rd November 2019 at UniMAP, Malyasia. Prof. Nogita was invited by A/Prof Arif Salleh who is a UQ PhD graduate under Prof. Nogita and Dr. McDonald’s supervision.

3. Presentation at Synchrotron workshop in Malaysia

(Prof Kazuhiro Nogita, Director)

Prof Nogita delivered a seminar titled “Advanced characterisation of materials: case studies” at Synchrotron Workshop on 24th November at Penang, Malaysia before EPITS2019.

4. Invited Speaker, “New Colombo Plan Mobility Program in 2019 “Electric Vehicle Manufacture and Supporting Industries in Japan - Creating Opportunities for Australia's Future Engineers -”, MAJIT seminar, on 23rd August 2019 at The University of Queensland.

(Prof Kazuhiro Nogita, Director)

Professor Kazuhiro Nogita had the privilege of addressing students enrolled in the Master of Arts in Japanese Interpreting and Translation (MAJIT). The MAJIT program provides high levels of competence and training in English and Japanese languages as well as theoretical and practical skills in translation and interpreting. The topic of Professor Nogita’s MAJIT seminar was titled “New Colombo Plan Mobility Program in 2019 “Electric Vehicle Manufacture and Supporting Industries in Japan - Creating Opportunities for Australia's Future Engineers -””. This discussed the activities of the 2019 Engineering course supported by a New Colombo Plan Mobility Program and took 15 UQ Engineering students to Kyushu University and a variety of leading Japanese manufacturing facilities.

Gallery

Our people

- Professor Kazuhiro Nogita

- Dr Stuart McDonald

- Mr Keith Sweatman

- Professor Trevor Abbott

- Professor Syo Matsumura

- Dr Dongdong Qu

- Dr Xin Fu Tan

Postgraduate Research Students

- Ms Syeda Umama Mehreen

- Mr Youichirou Kawami

- Mr Manjin Kim

- Ms Nurul Razliana Abdul Razak

- Mr Qichao Hao

- Mr He Tian

Postgraduate Coursework Students

- Mr Jiye Zhou, Master's Thesis Student 2021

- Mr Zherui Tong, Master's Thesis Student 2021

Undergraduate Students

- Mr Ahmad Amar Aiman Zulkafli, Undergraduate Final Year Thesis Student 2021

- Mr Dong Xu, Undergraduate Final Year Thesis Student 2021

- Mr Liam Young, Undergraduate Final Year Thesis Student 2021

- Mr Yaxuan Li, Undergraduate Final Year Thesis Student 2021

Graduated Research Students

- Associate Professor Dr Dekui Mu, PhD Graduate 2012

- Dr. Mu, Associate Professor at Huaqiao University, China.

- Professor Dr Guang Zeng, PhD Graduate 2014

- Dr. Zeng, Special-Term Professor, Wrought Magnesium Research Centre, School fo Materials Science and Engineering, Central South University, China.

- Associate Professor Dr Mohd Arif Anuar Mohd Salleh, PhD Graduate 2016

- Dr. Mohd Salleh, Associate Professor/Deputy Dean at the School of Materials Engineering and group leader at the Electronic Packaging Materials Research, University Malaysia Perlis (UniMAP), Malaysia.

- Dr Xuan Quy Tran, PhD Graduate 2017

- Dr. Tran obtained his PhD degree from the University of Queensland, and he is currently a Postdoc Research Fellow at the Ultramicroscopy Research Center, Kyushu University.

- Dr Matthew Gear, PhD Graduate 2019

- Dr. Gear obtained his PhD degree from the University of Queensland, and he is currently a Research Engineer at the Defence Science and Technology Group, Melbourne.

- Dr Yuxiang Hu, PhD Graduate 2019

- Dr. Hu obtained his PhD degree from the University of Queensland, and he is currently a Postdoc Research Fellow at the Australian Institute for Bioengineering and Nanotechnology, the University of Queensland.

- Dr Flora Somidin, PhD Graduate 2020

- Dr. Somidin obtained her PhD degree from the University of Queensland, and she is currently a Research Fellow at the School of Materials Engineering, University Malaysia Perlis (UniMAP), Malaysia.

- Dr Shiqian Liu, PhD Graduate 2020

Dr. Liu obtained her PhD degree from the University of Queensland, and she is currently a Postdoc Research Fellow at the School of Mechanical and Mining Engineering, the University of Queensland.

Dr. Liu obtained her PhD degree from the University of Queensland, and she is currently a Postdoc Research Fellow at the School of Mechanical and Mining Engineering, the University of Queensland.

- Dr Xin Fu Tan, PhD Graduate 2020

Dr. Tan obtained her PhD degree from the University of Queensland, and she is currently a Postdoc Research Fellow at the School of Mechanical and Mining Engineering, the University of Queensland.

Dr. Tan obtained her PhD degree from the University of Queensland, and she is currently a Postdoc Research Fellow at the School of Mechanical and Mining Engineering, the University of Queensland.

Graduated Coursework Master's Degree Students

- Mr Xiaozhou Ye, Coursework Master's Degree Graduate 2018

- Mr. Ye obtained his Master's degree student at The University of Queensland, majoring in Mechanical and Mining Engineering.

- Mr Jianzhi Yu, Coursework Master's Degree Graduate 2019

- Mr. Yu obtained his Master's degree at The University of Queensland, majoring in Mechanical and Mining Engineering.

- Mr Buddhi Gunatunga, Coursework Master's Degree Graduate 2020

- Mr. Gunatunga obtained his Master's degree at The University of Queensland, majoring in Mechanical and Mining Engineering.

Graduated Undergraduate Thesis Students

- Mr Charlie Berrington, Undergraduate Final Year Thesis Student 2017

- Mr. Berrington was an undergraduate final year thesis student at The University of Queensland, majoring in Mechanical and Mining Engineering. He graduated in year 2017.

- Ms Misaki Nakamura, Undergraduate Final Year Thesis Student 2017

- Ms. Nakamura was an undergraduate final year thesis student at The University of Queensland, majoring in Mechanical and Mining Engineering. She graduated in year 2017.

- Ms Nurizzettie Mazlan, Undergraduate Final Year Thesis Student 2017

- Ms. Mazlan was an undergraduate final year thesis student at The University of Queensland, majoring in Mechanical and Mining Engineering. She graduated in year 2017.

- Mr Amedeo Bruzzone, Undergraduate Final Year Thesis Student 2017

- Mr. Bruzzone was an undergraduate final year thesis student at The University of Queensland, majoring in Mechanical and Mining Engineering. He graduated in year 2017.

- Mr Daniel Costello, Undergraduate Final Year Thesis Student 2018

- Mr. Costello completed his undergraduate final year thesis at The University of Queensland in 2018, majoring in Mechanical and Mining Engineering.

- Mr Day Weng Tan, Undergraduate Final Year Thesis Student 2018

- Mr. Tan completed his undergraduate final year thesis at The University of Queensland in 2018, majoring in Mechanical and Mining Engineering.

- Ms Asanthi Dinithika Appuhamy, Undergraduate Final Year Thesis Student 2018

- Ms. Appuhamy completed her undergraduate final year thesis at The University of Queensland in 2018, majoring in Mechanical and Mining Engineering.

- Mr Adrian Xiao Bin Yong, Undergraduate Final Year Thesis Student 2018

- Mr. Yong completed his undergraduate final year thesis at The University of Queensland, majoring in Mechanical and Mining Engineering.

- Mr Muhammad Syahmi Abu Bakar, Undergraduate Final Year Thesis Student 2018

- Mr. Abu Bakar completed his undergraduate final year thesis at The University of Queensland, majoring in Mechanical and Mining Engineering.

- Ms Siti Nur Afiqah Ibrahim, Undergraduate Final Year Thesis Student 2018

- Ms. Ibrahim completed her undergraduate final year thesis at The University of Queensland, majoring in Mechanical and Mining Engineering.

- Ms Rhianna Cardamone, Undergraduate Final Year Thesis Student 2018

- Ms. Cardamone completed her undergraduate final year thesis at The University of Queensland, majoring in Mechanical and Mining Engineering.

- Mr Amirul Rifqi Ayub Zamri, Undergraduate Final Year Thesis Student 2019

- Mr. Ayub Zamri completed his undergraduate final year thesis at The University of Queensland, majoring in Mechanical and Mining Engineering.

- Mr Patrick Horsley, Undergraduate Final Year Thesis Student 2019

- Mr. Horsley completed his undergraduate final year thesis at The University of Queensland, majoring in Mechanical and Mining Engineering.

- Mr Anthony Smith, Undergraduate Final Year Thesis Student 2019

- Mr. Smith completed his undergraduate final year thesis at The University of Queensland, majoring in Mechanical and Mining Engineering.

- Mr Muhammad Hafiz Husain, Undergraduate Final Year Thesis Student 2019

- Mr. Husain completed his undergraduate final year thesis at The University of Queensland, majoring in Mechanical and Mining Engineering.

- Ms Nur Haleeda Abdul Ghani, Undergraduate Final Year Thesis Student 2019

- Ms. Abdul Ghani completed her undergraduate final year thesis at The University of Queensland, majoring in Mechanical and Mining Engineering.

- Mr Taiki Tomizawa, Undergraduate Final Year Thesis Student 2020

- Mr. Tomizawa completed his undergraduate final year thesis at The University of Queensland, majoring in Mechanical and Aerospace Engineering.

- Mr Julio Pinzon Piraquive, Undergraduate Final Year Thesis Student 2020

- Mr. Pinzon Piraquive completed his undergraduate final year thesis at The University of Queensland, majoring in Mechanical and Aerospace Engineering.

- Ms Caroline Shiwei Tao, Undergraduate Final Year Thesis Student 2020

- Ms. Tao completed her undergraduate final year thesis at The University of Queensland, majoring in Mechanical Engineering.

- Mr Gokhula Hari Kannan, Undergraduate Final Year Thesis Student 2020

- Mr. Kannan completed his undergraduate final year thesis at The University of Queensland, majoring in Mechanical and Materials Engineering.

- Mr Thomas Healy, Undergraduate Final Year Thesis Student 2020

- Mr. Healy completed his undergraduate final year thesis at The University of Queensland, majoring in Mechanical Engineering.

Contact

For more information about The Nihon Superior Centre for the Manufacture of Electronic Materials facilities, please contact us.

Professor Kazuhiro Nogita

Director

Nihon Superior Centre for the Manufacture of Electronic Materials

p: +61 7 3365 3919

e: k.nogita@uq.edu.au

- Digital fabrication and design

- Materials and manufacturing for a more sustainable world

- Materials and processes for extreme environments

- Research capabilities

- Nihon Superior Centre for the Manufacture of Electronic Materials

- Composites Group

- The University of Queensland – Kyushu University Oceania Project